Because fertilizer demand depends on a variety of agroeconomic factors it is not stable nor easy to predict. If actual fertilizer demand is less than the fertilizer produced, heavy financing costs and product losses will be the result. Considering that fertilizer manufactured but not sold may have to be kept for a year before it finds a buyer and that storage for a year can cause high quantity and quality losses, the consequences can be significant. If the actual demand is larger than forecast, this obviously leads to less revenue and profit but also potentially lower agricultural production.

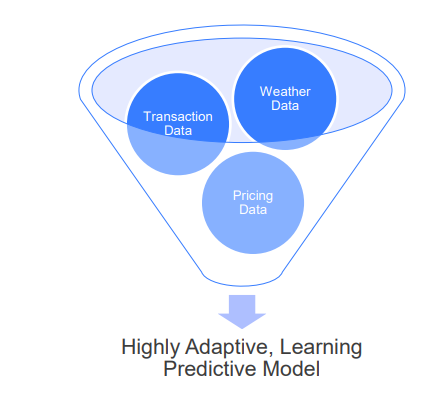

Using 30 years of historical data on sales, weather, market prices, farm gate prices, etc. this effort created an AI based prediction model which resulted in an 85% forecast accuracy, which was a substantial improvement over the previous methods of calculating demand.